Guidelines

- Home

- Guidelines

Laser Cutting

At Quote Cut Ship, our mission is to make ordering custom cut parts simple. Providing us with files that meet our guidelines allows us to provide you with the finished parts you need quicker.

As you put together your files, here are a few things to keep in mind:

- Your file should be in DXF format.

- Files should be built to scale.

- Don’t nest parts – files should contain only one part each.

- All objects should be within the same layer.

- Stray points, duplicate lines, empty objects, open entities, text areas, and unnecessary information should be removed.

- Text should be converted into outlines or paths with bridges.

- All shapes should be united, combined or merged.

- Avoid intersecting or common lines.

- Part files should not have open contours.

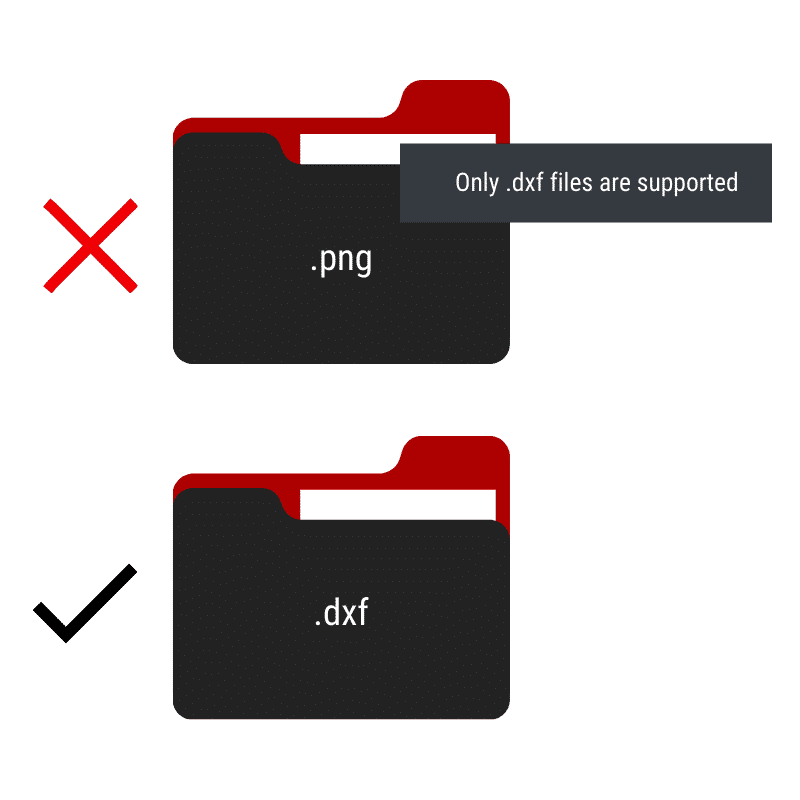

Your File Should be In DXF Format

Currently our instant quote system only accepts files that are uploaded in DXF vector format. We cannot process AI, EPS, DWG files or raster-type files such as BMP, JPEG, PNG, or TIFF.

If you don’t have access to CAD software to create your files you can always reach out to us for help with a conversion.

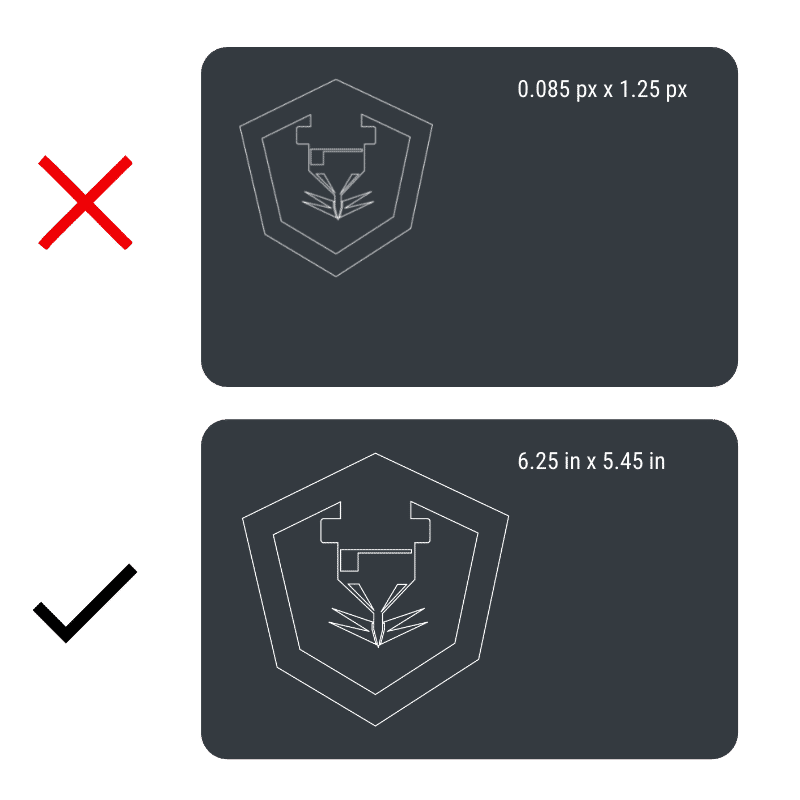

Files Should be Built to Scale

We pride ourselves on being precise, which is why we cut our parts to your exact specifications. We won’t adjust your design based on notes or written dimensions, even if you put them in the file.

Please convert your designs size units into inches or mm and ensure that the file is sized to a 1:1 scale before uploading.

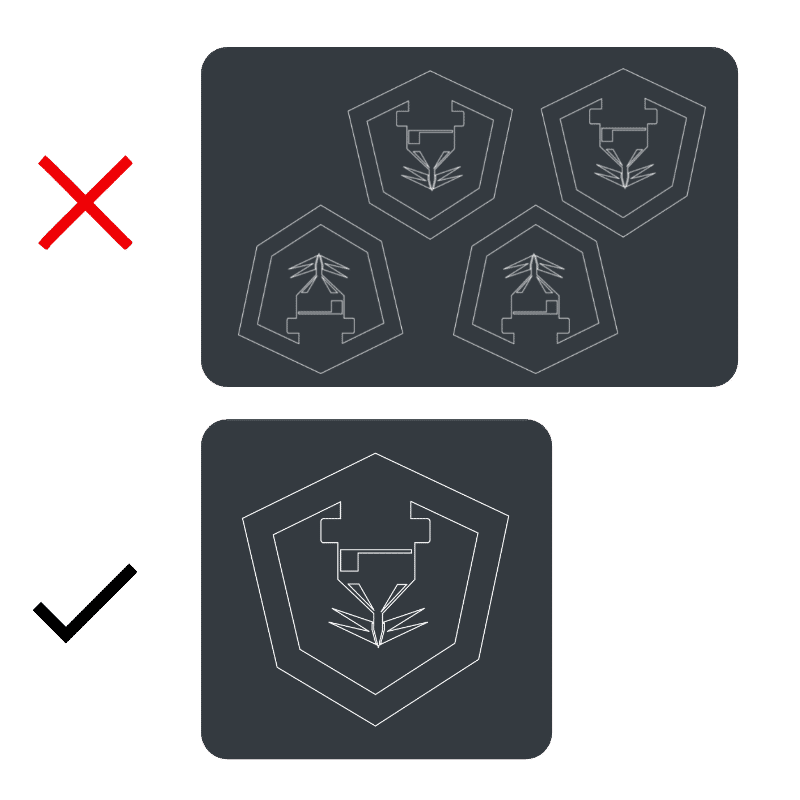

Don't Nest Parts - Files Should Contain Only One Part Each

Nesting your parts into one sheet on the same file may feel like a more efficient way to request your parts, but it can hinder our process and add to the time it takes us to fulfill your order.

Our advanced quoting tool uses your part files to determine the amount of material needed before providing a price. When files are pre-nested, it often results in a more expensive and incorrect quote.

When uploading your files, we ask that you upload files that contain only one part each. Don’t worry – we’ll handle the nesting!

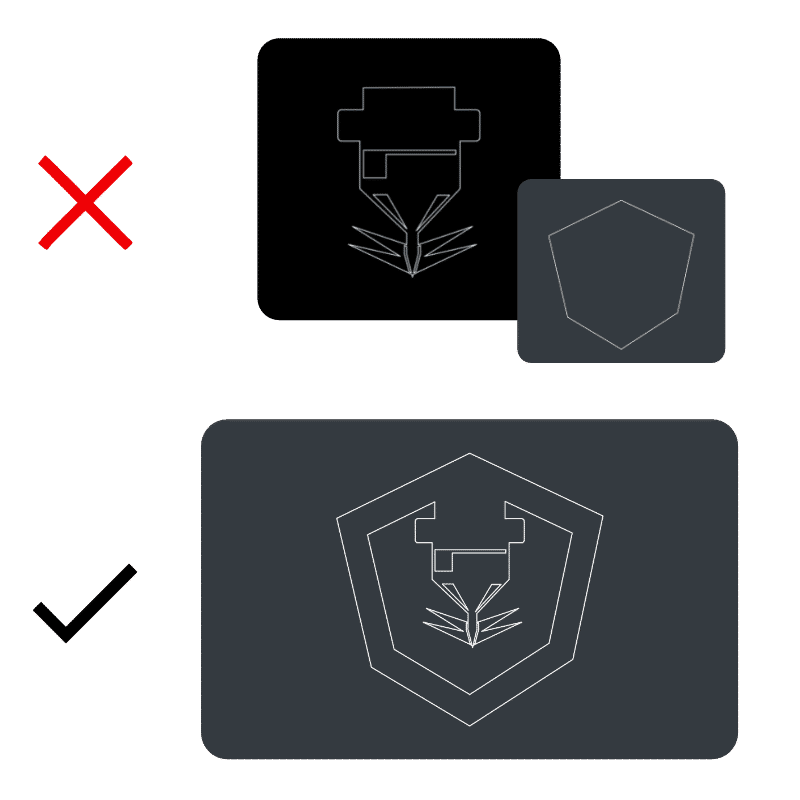

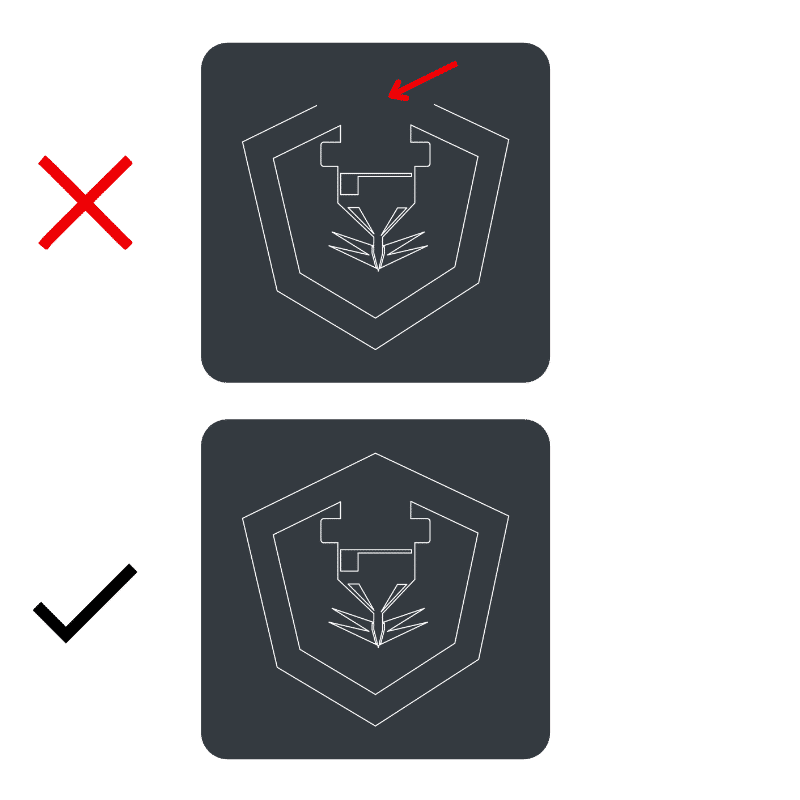

All Objects Should be Within the Same Layer

Each file you upload should contain only one layer with your part displayed in it’s entirety.

In the top example, the file is split into two layers. If this were uploaded to our system our software wouldn’t realize that this is supposed to be one part with the laser head on the left cut out.

Placing your design into one layer helps us properly identify where cutouts should be placed and what the finished part should look like.

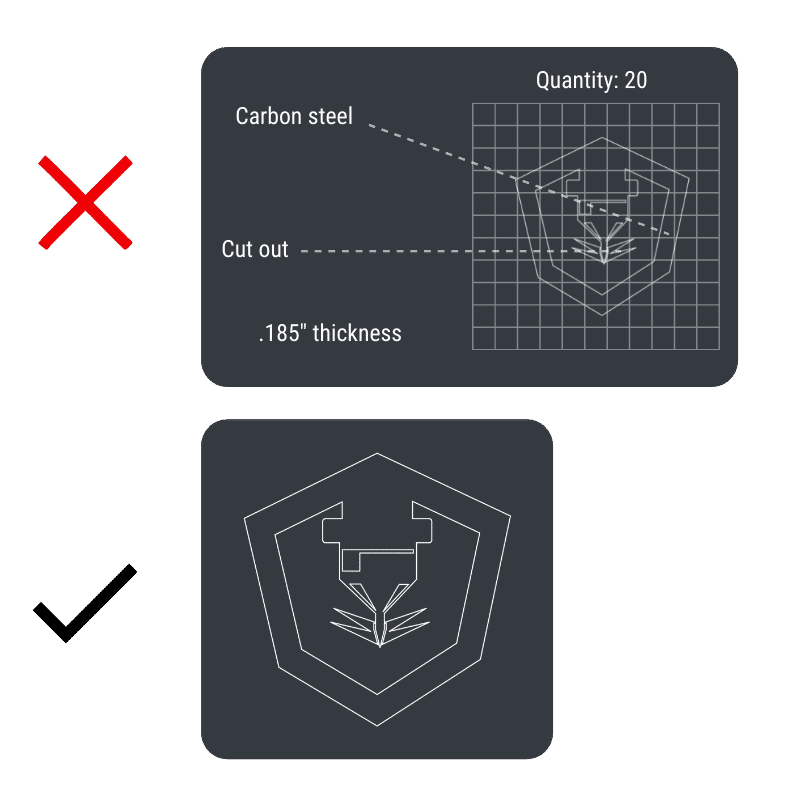

Stray Points, Duplicate Lines, Empty Objects, Text Areas, Open Entities, and Unnecessary Information Should be Removed.

Please remove everything but the part that should be cut from the file. This helps us fulfill your order faster and without any confusion.

You’ll have the opportunity to tell us the quantity you need and note any special instructions in a separate area while placing your order.

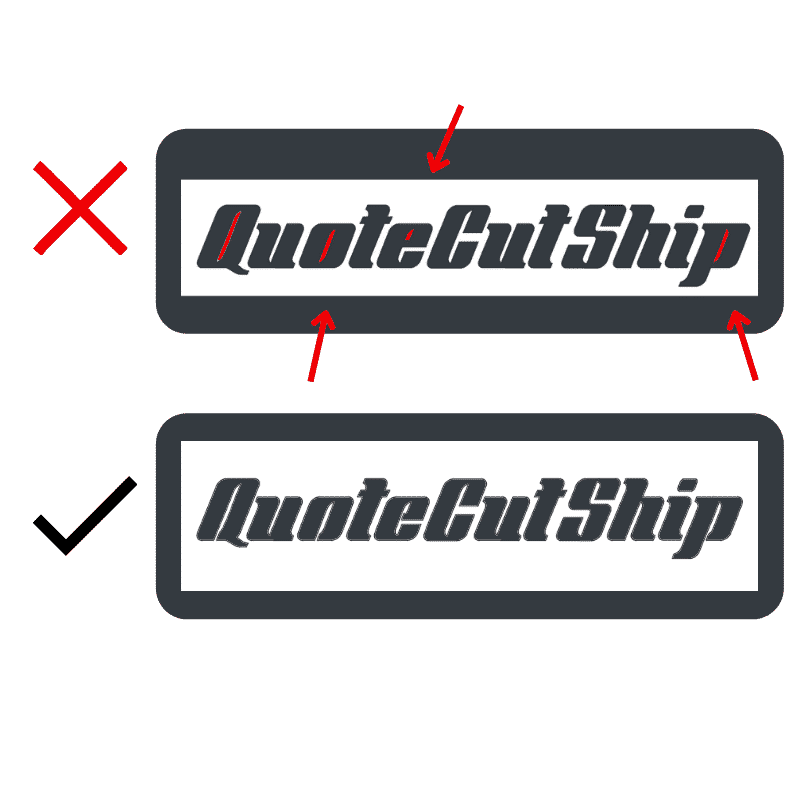

Text Should be Converted into Outlines or Paths with Bridges

If you’re designing a part that includes cut outs, it’s important that you remove those pieces from the file you upload as well.

This is especially true when uploading a design that includes text since many letters have cutouts that affect the readability of your design.

If the text is intended to be cut out from the finished product then it should be bridged together like a stencil. This helps avoid loose pieces that are hard to work with.

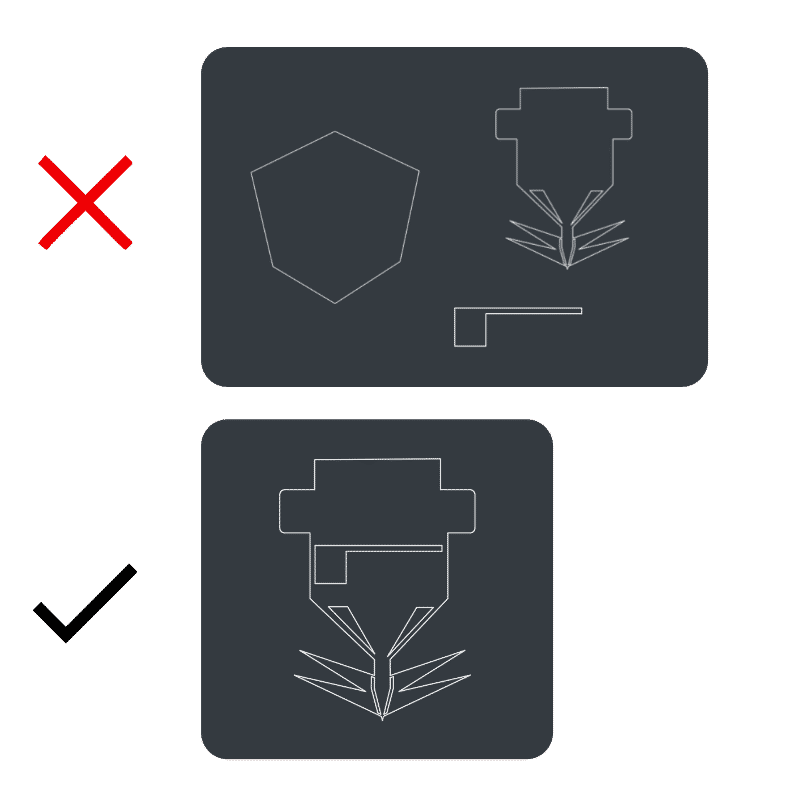

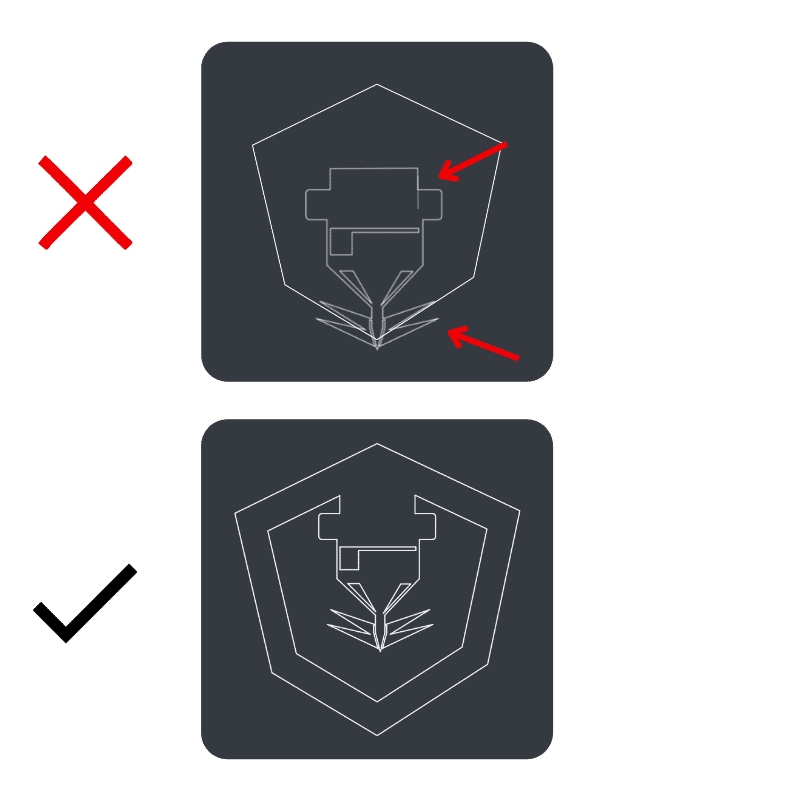

All Shapes Should be United, Outlined, or Merged.

You might think that separating your part into individual shapes would make the cutting process easier, but it actually makes it more difficult for us to determine what you’re looking for.

Grouping your part into one outline helps us know exactly what the finished part looks like and fulfill your order more efficiently.

Avoid Intersecting or Common Lines.

Overlapping lines are not only unsightly, they also affect our laser’s ability to cut your parts. Before uploading your files, we ask that you review your design and correct any areas where lines overlap or continue past the point where they should end.

Part Files Should Not Have Open Contours.

Open contours occur when a shape doesn’t connect all the way around. If the lines in your drawing don’t connect, our lasers won’t be able to cut out your part completely.

This example shows a large open contour, but even a small gap is problematic. To avoid having open contours in your file you should review it carefully and preview it in outline mode using your design software.

Order Your Parts Online in Seconds

Now that we’ve covered the specifics, are you ready to get started? Upload your design files and get a free instant quote online now.